Thursday

I knew things were bad when I discovered dust had got past my air filter! I immediately began to think what might need to be done to fix the damage. As I rode on it became evident that the damage was significant. Mawson used over 1L of oil in 200km.

Arriving here at the Lyon family home in the dark with an ailing Mawson, having never met them, was quite a big thing to lump on them. I was so very glad to have made it. No need to trailer the bike. Thank heavens f0r that! What I didn’t quite realise was just how much work was ahead of us. Nor did I know how lucky I was.

Donnie and Mathew (son) have a very well tooled workshop including some very specific tools that would be required to rebuild the motor like a valve grinder. Donnie did his apprenticeship recondition engines I believe.

Mawson without luggage, after his shower but before his open heart surgery in front of the Lyon surgery.

Part of the operating theatre (valve grinder left, all my crap on the benches that were lovely and clean when I started)

One things was clear to me from what I had seen, we had to open the engine and likely change at least the rings. The piston, bore and valves could all have damage too.

We wouldn’t know how bad it was until we opened it, however I was painfully aware that parts would be the hold up even if ordered immediately. I was also aware that Kawasaki Australia was unlikely to have the required gaskets in the country. There wasn’t even a clutch cable for Raman’s bike in the country. This tends to mean over three weeks wait for it to be ordered in.

I ordered some parts in Rockhampton nearly 3 weeks ago and they have not arrived yet.

Everyone is at work as it is Thursday. All we have done is arrive and tell them what has happened. Donnie said we could open it up and have a look when he gets home. With all this in mind I decided to get right to the point first thing this morning and order a full piston kit direct from Eagle Mike in the US.

The KLR guru

The go to man for all things KLR in the US is Eagle Mike. Anyone who knows KLRs knows what the “doohicky” is. Eagle Mike is the guy who makes the upgraded ones. He has very well priced and very good quality kits on his site so I ordered all the parts I might need from him and got them posted express. The whole package including US$100 freight was AU$500. All the gaskets, a forged custom JE piston, rings and KLX needle and jets.

So that was over a week ago.

Donnie and Donna Lyon have been amazingly hospitable, putting us up like old friends.

I walked up Castle Hill in Townsville with them on Saturday morning early before taking advantage of the salt water for a refresher after the excursion up Castle Hill.

Townsville and The Strand from Castle Hill (looking east)

Looking north (Donnie left)

The bike has the my primary focus although I have had a chance to do a few other things including ride Matt’s Husaberg 570 on a rough trail and on the loose sand of the dry Black River. Wow! What an amazing experience. Sore arms after 5 minutes. And, damn I can actually ride on sand…with the Husaberg at least. Amazing hardware. I was able to get up and go fast and slow down without trouble or fear of coming off. Doing 80+ on sand without a problem. Handles rough trails and huge ditches like nothing else I have ever ridden. Not a bike for what we are doing but an amazing experience none the less.

Husaberg FE570 similar to Matt’s. Matts has nearly double the horse power of a klr650 and suspension better again.

We pulled the motor down, inspected the damage and got to preparing the bike as best we could.

The head off. Our first look at the inside.

Carbon deposits on the top of the piston from all the oil burning.

We had to wait for the piston before we could bore out the cylinder.

The bike fully stripped down with the subframe off to get the air box out to allow a really good cleaning of all the mud and dust that got into every corner.

Gee, Mawson looks different like this!

Matt cleaning the head in the parts cleaning bay (kero)

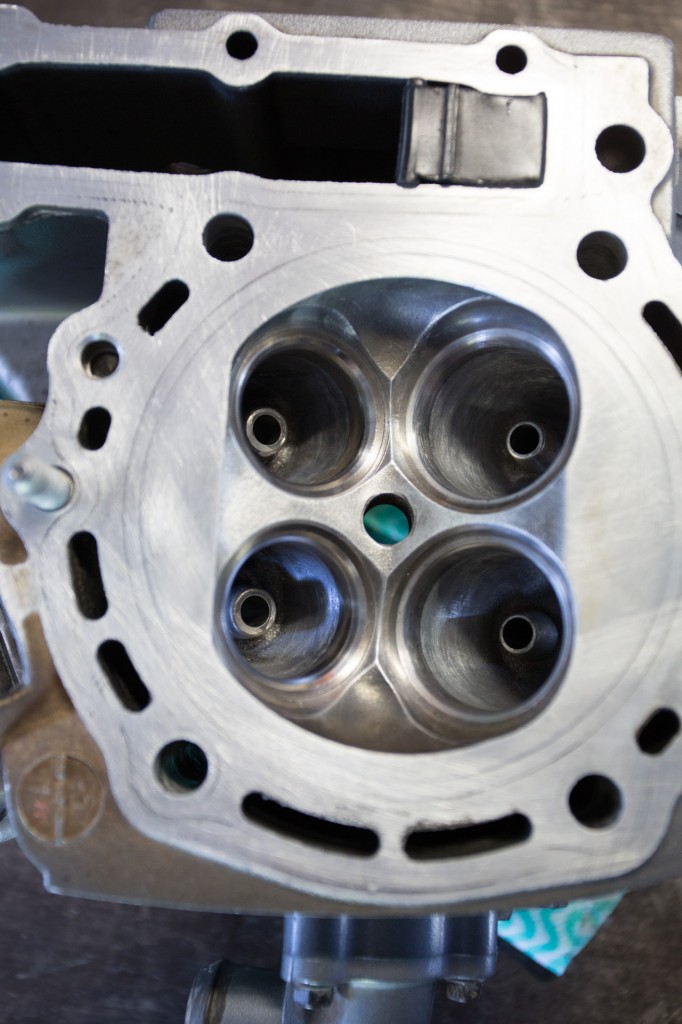

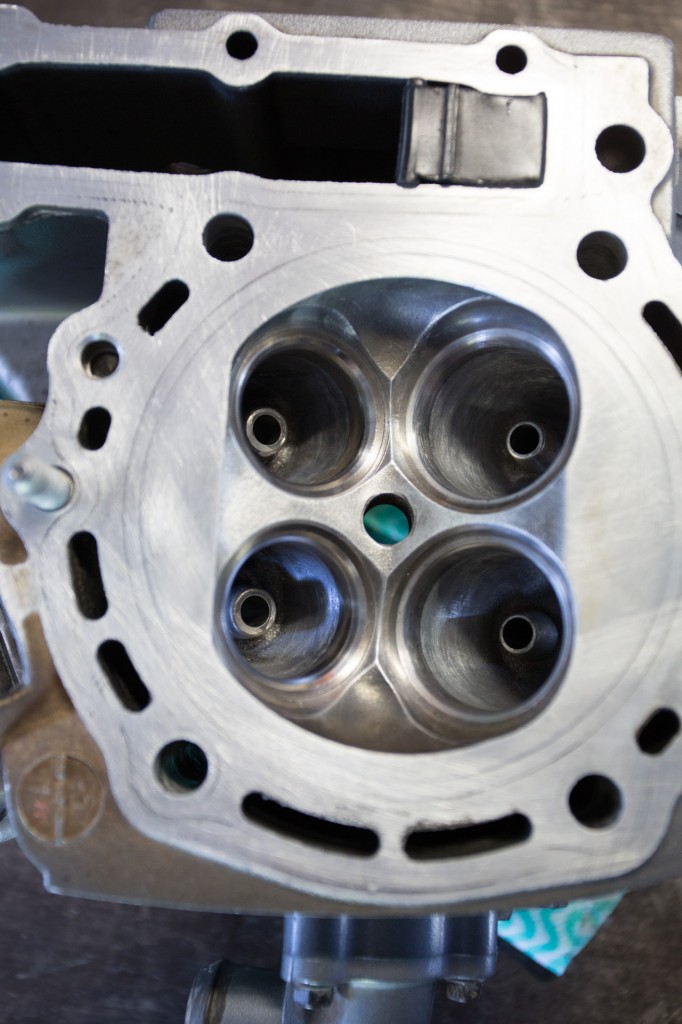

After hours of porting work to blend the valve seats into the ports (and grind a bloody huge bit of a bolt that had carelessly been over threaded into the port. Presumably a design fault, not an assembly fault)

Head underside view showing cleaned up inlet and exhaust valve ports. Note they have not been polished to a high shine. That final step in port did not seem worth it on such a rudimentarily designed head.

After lots of waiting the parcel turned up early on Friday morning (over a week later). Thanks Adrian for dropping it off.

The new forged 685cc (2,5mm overbore) piston from Eagle Mike by JE Pistons.

I had the piston and cylinder to the mate of Donnie’s, who had worked boring cylinders all his life and he is 53 I think, by 9:15am.

Got it back by 11:30am, got oil, coolant and a bunch of other little things and got to putting it all back together. Friday has been a big day!

Donnie gapping the new rings

Piston and cylinder installed, head gasket going on.

Head detail

It is late. Most of the work is done. Tomorrow morning we find out if it starts.